Alimentos y Bebidas

Permite que las organizaciones de alimentos y bebidas cumplan con múltiples estándares, regulaciones e iniciativas, como los esquemas HACCP, ISO 22000, FMSA y GFSI (FSSC 22000, SQF, BRC, IFS, etc.).

En BP&C contamos con una amplia experiencia en la industria agroalimentaria, gestionando, optimizando y automatizando procesos al igual que ofreciendo diferentes soluciones tecnológicas para satisfacer las necesidades de la industria. Desde sistemas transaccionales (ERP, MRP, MES, PLM, Maintenance...) a sistemas de conformidad reglamentaria (EQM, Auditoría, Ambiental...).

FSM | Calidad Alimentaria

Sistema integrado de gestión que atiende a las necesidades específicas de la gestión de la calidad de los alimentos, proveyendo una estructura de recursos modular que automatizan y simplifican los procesos de calidad de los alimentos.

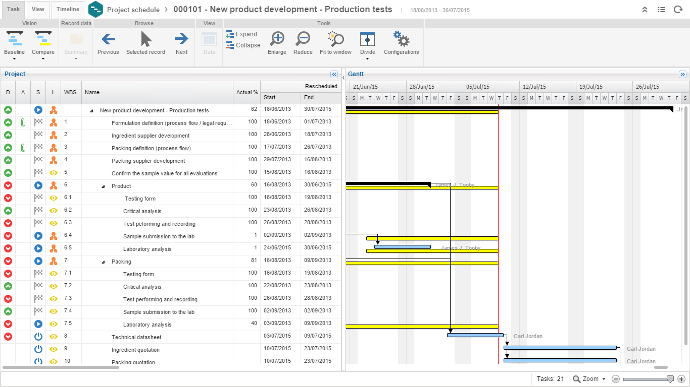

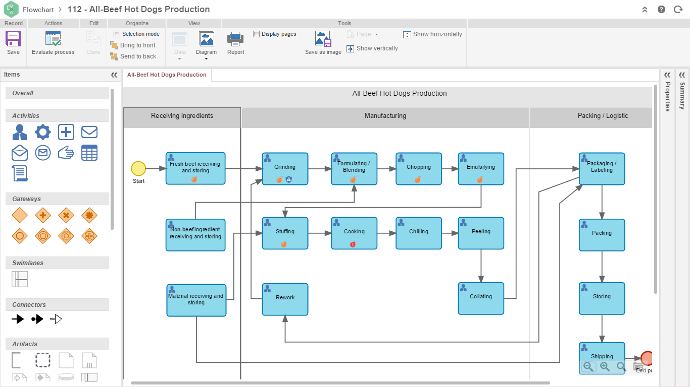

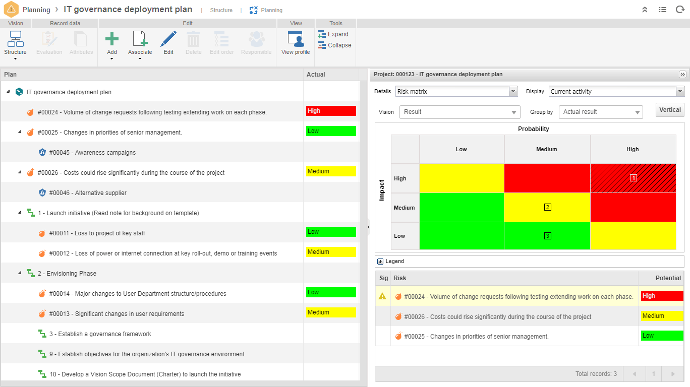

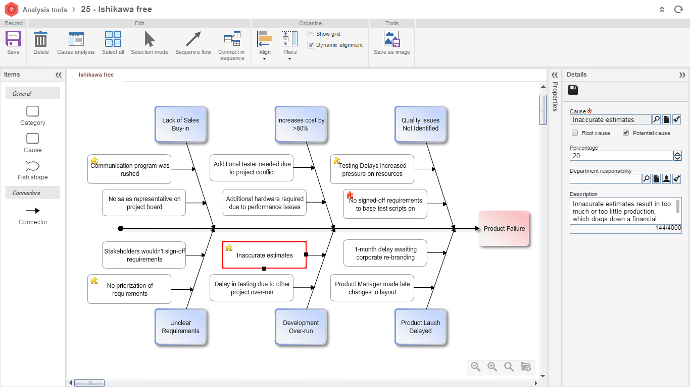

Relaciona la estrategia del negocio a las cuestiones de la calidad de alimentos, análisis de causa y acciones correctivas/preventivas. Va a administrar eficazmente los procesos de calidad y conformidad a través del mapeo de procesos y automatización, tratamiento de reclamaciones, gestión de auditoría, indicadores de desempeño, y mucho más – mejorando la satisfacción del cliente y reduciendo los costos de gestión.

FSM | Seguridad Alimentaria

La gestión de seguridad alimentaria es una de las áreas que más ha sufrido alteraciones en las empresas. Existen también una variedad enorme de estándares internacionales de seguridad alimentaria, variaciones entre estos estándares, formas de implementación y auditorías. Automatiza de forma efectiva y eficiente los programas de seguridad alimentaria para alcanzar un mejor control por medio de informaciones en tiempo real, mejores resultados, y garantía de seguridad.

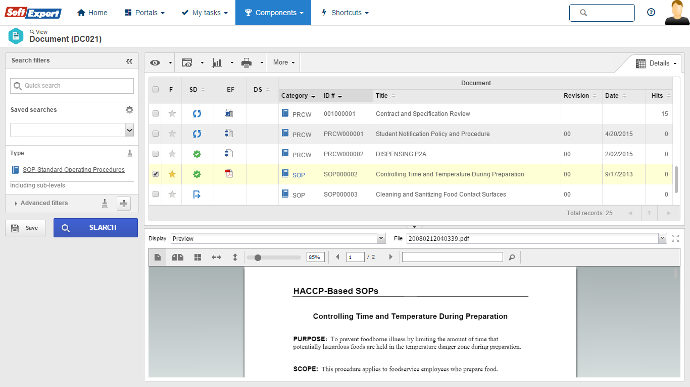

Facilita la gestión de seguridad alimentaria. Conduce la empresa a través de la creación de un plan de seguridad global de alimentos con el conocimiento y los procedimientos necesarios para hacer el trabajo correctamente. Las principales disciplinas relacionadas están completamente cubiertas, incluyendo gestión de proveedores, procedimientos/políticas, gestión de procesos, acciones correctivas/preventivas, monitorización de indicadores/controles, auditorías y mucho más. El escenario completo para un sistema de seguridad alimentaria.

- Registra y trata reclamos de clientes, no conformidades e incidentes, así como las acciones correctivas y preventivas resultantes com facilidade.

- Administra la especificación del producto y su lista de componentes (Bill of Material) en un ambiente centralizado y seguro.

- Garantiza la gestión de procedimientos, políticas y registros de forma consistente.

- Identifica, analiza y mitiga los riesgos en todo el proceso productivo.

- Mantiene los registros de auditoría para garantizar la conformidad.

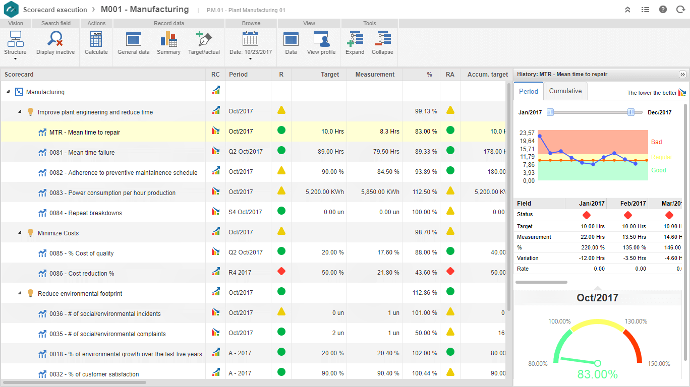

- Alimenta, monitorea y publica indicadores de desempeño promoviendo el alineamiento corporativo.

- Mapea las competencias organizacionales y habilidades para identificar deficiencias y enfrentarlas con planes de desarrollo orientados.

- Mantiene los registros de entrenamiento actualizados.

- Realiza todas las actividades de la administración de la cadena de abastecimiento, evaluando a proveedores y garantizando materia prima de calidad.

- Aumenta la produtividad mediante la administración del mantenimiento y de la calibración de los equipamientos.