Automotive & mobility

The automotive industry is facing a moment of broad and transformative changes. The rise of new players, increased environmental regulations and new safety standards are raising costs and making business more complex. Companies need to review their strategic priorities and develop the resources and skills required to achieve their goals, if they want to achieve profits, growth and long-term success.

At BP&C we have an extensive experience in the automotive & mobility industry, offering different software solutions to meet the specific needs of the industry. For transaction processing systems (ERP, MRP, MES, PLM, Maintenance...) to regulatory compliance systems (EAM, EQM, Audit, Environmental...).

Automotive & mobility Solutions

Than lowers the cost of regulatory compliance and helps companies in the automotive industry to maximize success, increase productivity, reduce risk and adhere to global regulations such as IATF 16949, ISO 9001, ISO 14001 and ISO 45001.

Solutions than provides a common framework and an integrated approach to manage multiple aspects of quality, environment, corporate governance and compliance. It can be easily deployed at all kinds of automotive companies, ranging from small-parts manufacturers, aftermarket parts and Tier 1, Tier 2 or Tier 3 suppliers, to OEM and global automotive manufacturers.

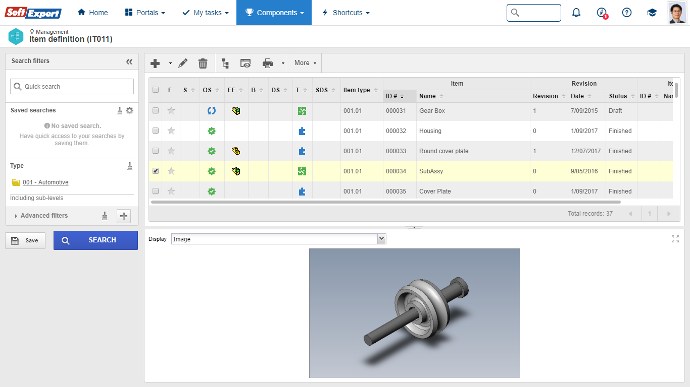

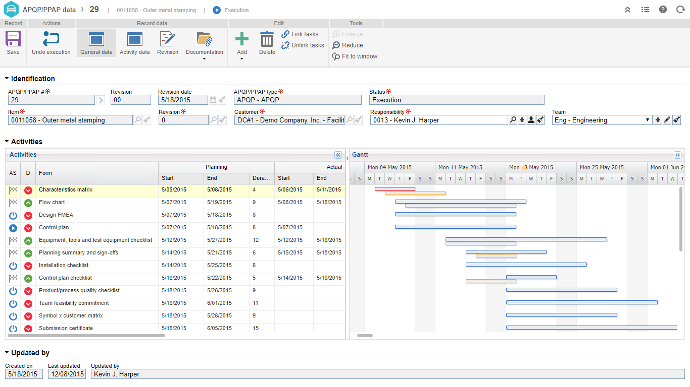

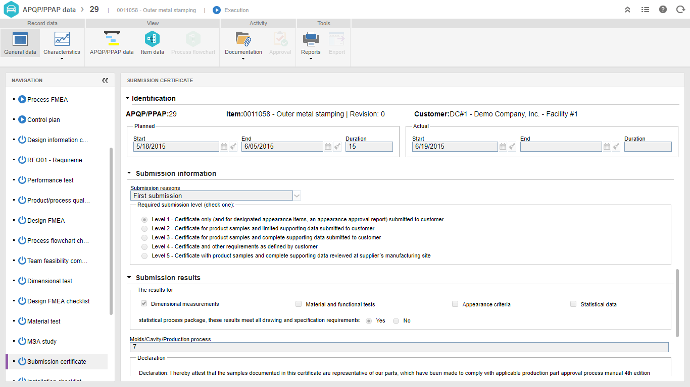

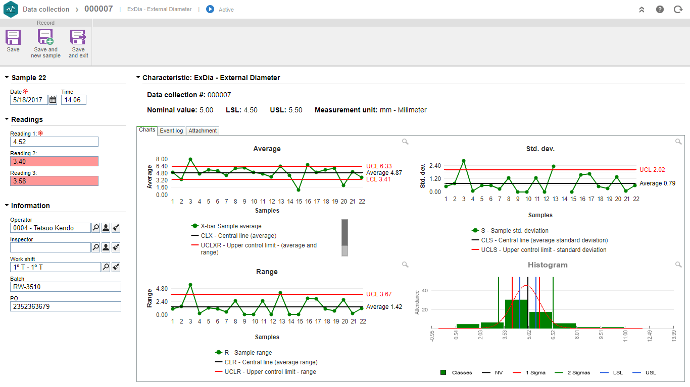

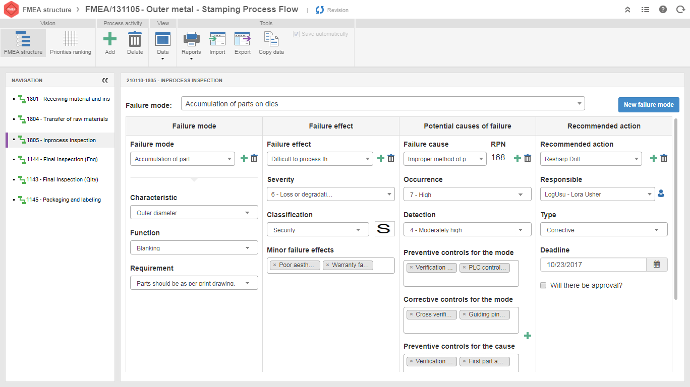

Solutions than enables automotive organizations to analyze and continuously improve process efficiency by using a single platform to integrate different management tools including product development management (PDM), advanced product quality planning (APQP), failure modes and effect analysis (FMEA), statistical process control (SPC) and measurement system analysis (MSA).

Simplifies and standardizes excellence and compliance management by providing a central point of access for all up-to-date process-related documentation, such as policies and procedures, process KPIs, audits, non-conformance reports (NCR/NCMR), and corrective/preventive actions (CAPA), as well as instrument calibration and asset maintenance, risk assessment, project management and strategic initiatives, work incidents, and waste management, among others.

- Optimizes business processes and streamline day-to-day operations.

- Drives effective compliance with different quality standards.

- Strengthens compliance with industry regulations, including IATF 16949, ISO 9001, ISO 14001 and ISO 45001.

- Improves collaboration between Engineering and the Quality Department.

- Anticipates product failures, preventing them and avoiding unnecessary costs.

- Provides seamless integration with MRP/ERP/CRM packages, through web-service interfaces.

- Provides real-time visibility of non-conformances in the quality management process for investigation and corrective actions.

- Facilitates Bill of Material (BOM) management and performance of changes, preventing deviations.

- Simplifies management of CAD drawings with a native MCAD connector for the PDM component.

- Issues electronic calibration certificates for internal and external customers, increasing regulatory compliance.

- Automatically calculates process indexes - average, amplitude, maximum and minimum values, z inferior and z superior, percentage of non-conformance items, Cp, Cpk, Pp, Ppk, control limits, normality test, kurtosis, asymmetry, sequence, trend, and standard deviation.

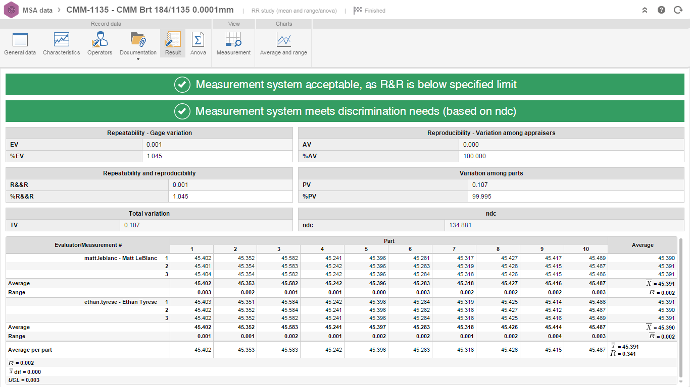

- Measures system analysis with Linearity, Amplitude, Trend, R & R (Average and Amplitude/ANOVA and Attribute) studies.

- Displays the hierarchy of all FMEA structure from the first level (product or process and their functions) down to the lowest levels (recommended actions) and automatically generates the FMEA form

- Ensures conformity with standards and regulations.